Introduction

In everyone’s life there comes a time where you need to select the right castor wheels to go with your latest modular kitchen, or you want to make the tables, cupboards, drawers’ moveable, or maybe your lovely office chair’s cheap plastic caster has given up and have made sitting over it frustrating.

Choosing the right Castor can be a daunting task in today’s space where you are overwhelmed with countless choices ranging from different sizes, materials, features, uses and so on. Look no further because here we are going to break down all the things necessary you should see before choosing the next castor wheel for your dream project.

Where do you intend to use the Castors?

The first and foremost thing you must keep in mind while selecting the Castor wheel is what purpose does it serve? Or where do I intend to use this castor?

Castor wheels are made for various use cases and you don’t want to be using the Castor made for indoor, smooth floor use cases like for furniture and office use in outdoor rough flooring conditions.

Indoor Castors

Castors made for indoor uses generally use wheels made of plastics like PPCP (Polyethylene-Polypropylene Copolymer) or nylon. These plastics are sufficient for marble and tiled flooring with minimal wear and tear. For example all of our castors use 1st grade PPCP or nylon polymer.

Indoor castor wheels can be further divided into specialized classes depending on their use cases.

Division of Indoor Castor Wheels

Castors for furniture

After putting countless hours with your interior designer to make your dream home the way you imagined. You wouldn’t want your experience to get ruined by the failing of a cheap Castor wheel.

You can get multiple colour options in wheels and metal housing in furniture Castors. We provide both orange and white colour option in some of our Castors.

Furniture Castors come in variety of different shapes and sizes depending on the use cases, the most popular ones are

Six Wheeler (Sixer)

Six wheel type caster wheels are perfect for heavy furniture and kitchen applications like

- Tables

- Sofas

- Modular kitchen cabinets

- Beds

- Cupboards and Almirahs

Single, Double or Ball type Castors

More often than not they come with some kind of swivel mechanism to allow them to revolve around their axis. The most common types of swivel mechanism found are either thread /Stem type or fixed plate type.

The installation of thread/stem type Castors is easier because you only have to just put the thread/stem (bolt) in the provided space in the trolley or chair legs which have nuts pre-installed.

Whereas in the case of plate type attachment you will need to screw four nuts and bolts and might even need to drill the holes if not provided in the place of installation. Swivel type castors are best suited for

- Chairs

- Trollies

- Cooler Stands

- Shopping Carts

- Trams

Swivel mechanism can be further divided into two types Kingpin and Kingpinless Mechanism.

Generally Kingpin mechanism uses a Kingpin (bolt or rivet) to hold the whole assembly together where as in Kingpinless mechanism as the name suggests uses no bolt or rivet to hold the assembly. You can read further about differences between kingpin and Kingpinless mechanism here.

These are just the most popular shapes in which you can find domestic castor wheels there are many other shapes like Ezee Roll’s Flat Two wheel Castor which can be substituted for six wheeler if you are on a lower budget or want something for smaller places like for drawers.

You can also find many other features like bearings, double moulded wheels, brakes, locking mechanism which we will cover later in this article.

Hospital Castors

Although you will be fine using the any type of Castor wheel mentioned above for hospital beds, trollies, wheel chairs etc. But if you want to provide the best experience for your patients you must be looking for additional features like

- Almost silent working which can be achieved by the use of bearings, use of soft materials like PU (Polyurethane) or rubber covering over the wheels or maybe the combination of all.

- Electronic height adjustment or breaking mechanism. Fallshaw’s Trinity EBC range is perfect for such use case. Trinity EBC builds on this innovation with the addition of automatic brakes, intuitive steering, and the ability to control the brakes and steering from any castor foot pedal, handset or nurse panel. So with Trinity EBC, you get a castor that knows where you want to go, and knows when you want it to stop.

Industrial Castor Wheels

What’s actually different in industrial Castor wheels?

On surface you won’t find much difference between the Premium domestic Castor wheels mentioned above and industrial Castor in terms of design apart from their size. They are generally greater than 12 cm in height and there is a good reason behind that and it’s their higher dynamic weight capacity. They are made for more than 100Kg dynamic weight capacity for each castor and better durability in mind.

The shape of the Castor wheel will depend on the place you need to put it in. Example for heavy machinery which isn’t supposed to be moved as much as trollies that are used to transport stuff from one place of the plant to other you are better of using the flat type caster wheels with six or four wheels and for the latter you should you swivel type single/double wheel Castors.

Outdoor Castor Wheels

Some of the most difficult challenges for casters are found in outdoor terrains. Outdoor Castor are generally have big threads and use wheels that are made up of rubber for more grip. They are also expected to work in greater temperature range due to changing outdoor conditions. Because of all these conditions you should choose the Castors made with materials that have high durability, strength, wide temperature range and abrasive resistance. We are going to cover materials differences later in this article.

Weight capacity of the Castor

No one would like to see their Castors get crushed the moment you try to move the item. That’s why it is very much necessary to calculate the dynamic weight capacity under which the Castors are expected to move. Then move on to find the Castors which are rated for the specific weight.

Another thing worth noticing while purchasing the Castors on basis of the weight capacity is to whether the weight capacity is mentioned for the whole set of 4 or 6 pieces combined in the set or it’s mentioned for the single Castor.

For example: If you need castor wheels for 100 kg table, you will need four castors of at least more than 25kg (4 * 25kg = 100kg) capacity rather than a single Castor of 100kg capacity.

Generally Castors bigger in size are made for higher weight capacity but you can also find small Castors with greater durability made for high weight capacity like our Mini Sixer and Two wheeler.

Shape and Size of Castor

If there was a “One size fits all” solution, life would be much easier but it isn’t the case in reality. Just the way you can’t use car tyres on an airplane the same way you shouldn’t be using small cheap Castors on heavy moving stuff.

This thing might sound stupid to some of you that who would in their right mind will use car tyres on a truck or airplane or vica versa but you wouldn’t believe how commonly we see people buying small Castors with less weight capacity for undercutting and later end up spending more in long run.

You might think bigger the better and bigger the size of Castor the more weight it can handle. Right?

Actually not so much. While small size comes with its own limitations and they generally can’t handle as weight as their bigger brothers. Some manufacturers do shady business and never tell you the correct weight capacity of their Castors because they are using low quality materials and you end up buying low quality castor which doesn’t suit up with your furniture or other item. Whereas you would have gotten the right size of Castor with the required weight capacity if you would have done some research on the material. Which brings us to our next topic of this guide quality and materials differences.

Quality of Castors and materials differences

Although it’s a topic which deserves an article on its own and we will be soon writing about it in detail. So to not miss it subscribe to our news letter to get the update.

Here we are going to discuss some basic stuff in short like

Material of housing

Sheet metal and plastic are two materials which are used for making castor housing.

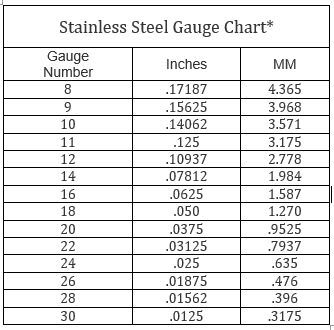

It’s obvious that metal is more durable than plastic for the castor housing but all metals are also not same. Metal thickness is commonly measured in Gauge scale and lower the gauge number thicker the metal. Which means more strength and durability.

Type of colour or coating used on metal housing is also a thing to pay attention at. Zinc coated or galvanized sheets catch rust faster than powder coated sheets.

Quality of wheels

Wheels are the most important part of the Castors and they are the biggest point of failure whether due breakage or wear and tear. They are generally made up of plastics and rubber. And plastics come in different type which is evident from comparing polyethene bags to bakelite switches.

Rubber is used for castors which are used on rough surface because it’s cheaper than plastics like polyurethane which keep the cost low but can also wear out quickly.

Types of polymers used for wheels in castors

Polyurethane or PU

Expensive polymer and can provide almost silent and smooth interaction with surface.

Nylon and PPCP (Polyethylene-Polypropylene Copolymer)

Nylon and PPCP are both great polymer and most widely used in castors which provide good durability at affordable price if you are fine with some moving noise, although they can leave their marks on tiled floor if used with high load. Nylon is also somewhat stronger than PPCP.

Other plastics like phenolic

You must remember seeing a castor like this in the image at some point in your life. Black wheels and cheap zinc plating. They are most readily available due to the use of cheap polymer/plastic called phenolic. Although phenolic has high weight capacity but only in static condition and that’s exactly what castors are NOT meant to be. It has low abrasive resistance and swell up if exposed to water. Can chip easily on rough surface and leave marks on the floor. They come at a cheaper price at cost of being expensive later in life due to issues.

Another method to differentiate between the plastic qualities of castor wheels just by looking even at their image in most cases, is by looking at their colour. Plastics can be recycled many time (apart from bakelite) therefore the Castors you see in colour apart from white are made from low grade recycled plastic which is cheaper but also less durable than the first grade plastic. Generally darker the colour lower is the quality of plastic used unless specified. Black is the most weakest. Therefore we here at ezee roll only use 1st grade polymers for our every castor.

Some extra features you can find in castors

With so much advancement in manufacturing process you can find something as simple as a castor wheel with so many extra features for your specific requirements. Some of them include

- Brakes

- Use of bearings in wheels for smoother rotation

- Swivel locking to fix position

- Height adjustment

- Torque adjustment for better swivel and rotation control

- Double moulding of other secondary material for wear and tear resistance

If you ever need any further assistance in choosing the right castor wheel for your dream project feel free to Ezee Roll’s customer support at any time to get the personalized buying experience and expert guidance.